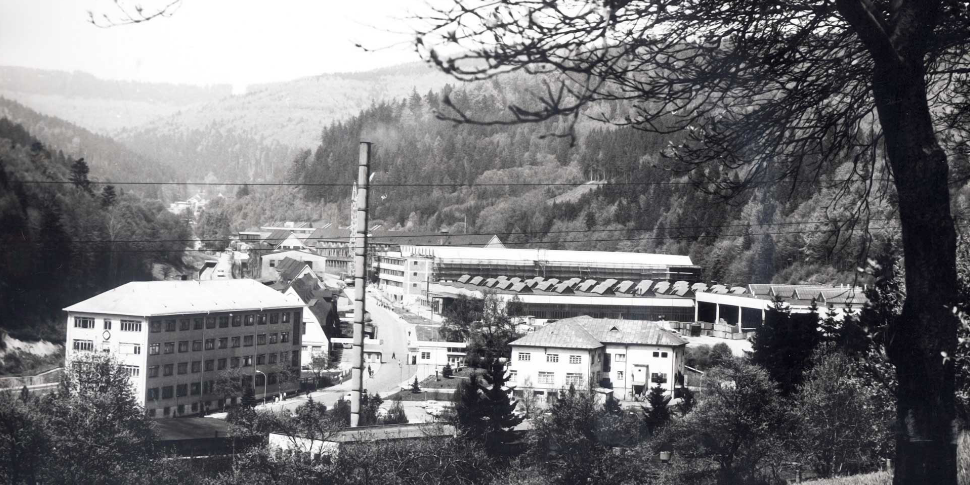

When the construction of the hardening plant in Vsetín started in 1938, no one thought of anything other than the coming World War II. And weapons were the products that the hardeners produced until 1945.

After the war, the heat treatment for textile machines, various types of gearboxes, sewing machines, mopeds, Skoda Spartak and Octavia cars, Tatra 603, tools and implements were added to the weapons. This period was terminated by the fall of the Comecon and the disintegration of the Eastern Bloc.

After 1999, we have been processing parts for more than 200 active customers from all possible industries, including among others forging, pressing, machining and founding.

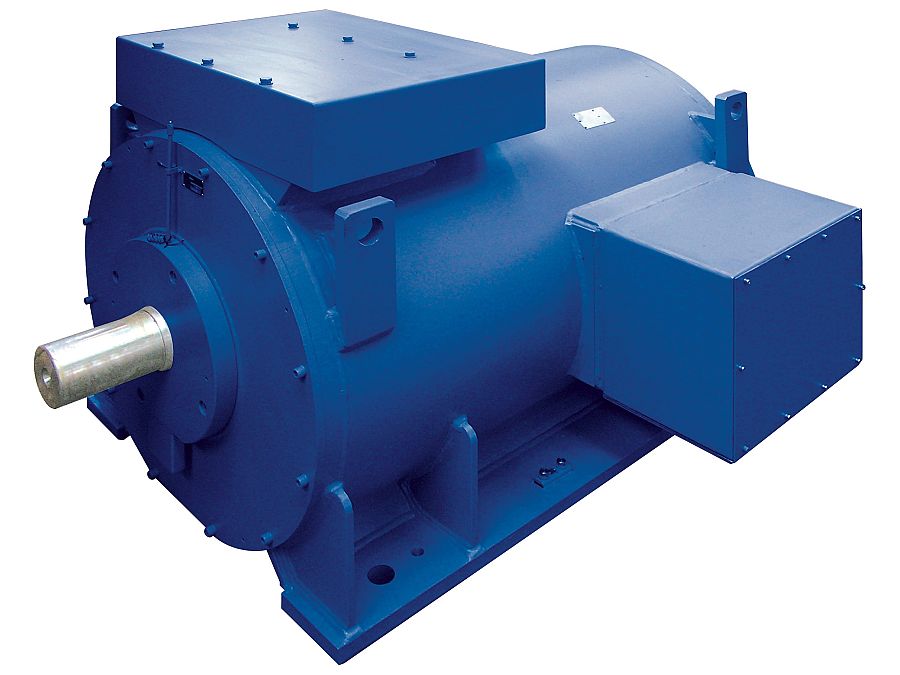

Thanks to the American NADCA standard for the heat treatment of molds and tools, we have a precisely designed system for tool shop orders. When you come to visit or to have a business meeting today, you will see parts for hydro and wind power plants, tractors, harvesters, handling transport equipment, cars and trucks, bridges, food machines, heavy machine tool assemblies, excavators, glass machines and in recent years also parts for aircraft, aircraft engines or snowmobiles. And because we honor the foundations given by our founding fathers, we also work for the Czech defense industry. We are a member of the Association for Heat Treatment of Metals in the Czech Republic and as an engaged member we benefit from educational programs and conferences.

.jpg)

.jpg)